Semi auto blow machine

Taizhou Fupusi Machinery Co., Ltd. presents the S Series semi-automatic blow molding machine, engineered for budget-conscious and space-optimized PET bottle manufacturing (capacity: 100ml–30L).

Core Advantages:

✔ Operational Simplicity: Touchscreen interface with rapid onboarding capability

✔ Durability: Heavy-duty components minimize operational interruptions

✔ Multi-Application: Compatible with containers for beverages, chemicals, personal care, and agrochemicals

- Technical Specification Style

Capacity Range: 100ml – 30L

Applications:

- Beverages: Water, soda, and other carbonated drinks

- Household Products: Cooking oils, cleaning agents

- Specialty Containers: Cosmetics, pesticide packaging

Target Market:

- Budget-conscious startups and SMEs entering the blow molding industry

- Facilities with spatial constraints

- Manufacturers needing rapid mold transitions for diverse product lines

- Marketing-Oriented Style

Versatile Performance: Handles containers from 100ml to 30L with precision.

Broad Compatibility: Perfect for bottling water, oils, cosmetics, and even agrochemicals.

Designed For:

- Small businesses looking for a cost-effective entry into blow molding

- Compact production environments

- Flexible operations requiring frequent product changeovers

- Concise Bullet-Point Style

Technical Highlights:

- Capacity: 100ml to 30L

- Applications:

- Beverages (water, sodas)

- Household (oils, detergents)

- Specialty (cosmetics, pesticides)

|

项目 |

Item |

unit |

FPSB3L |

FPSB2L-4 |

FPSB5L-1 |

FPSB5L-2 |

FPSB10L-1 |

FPSB20L |

|

|

瓶型规格 Bottle type Specification |

瓶子最大容量 |

Max. Volume |

L |

3 |

1.2 |

5 |

5 |

10 |

20 |

|

理论产量 |

Output |

PCS/H |

700-900 |

1500-1800 |

350-450 |

500-600 |

250-350 |

200-280 |

|

|

最大瓶子高度 |

Max. Height |

MM |

300 |

300 |

400 |

400 |

450 |

550 |

|

|

最大瓶子直径 |

Max. Diameter |

MM |

135 |

105 |

180 |

180 |

220 |

260 |

|

|

瓶子口径 |

Neck Size |

MM |

100 |

38 |

120 |

140 |

38-65 |

38-65 |

|

|

腔数 |

Cavity |

PCS |

2 |

4 |

1 |

2 |

1 |

1 |

|

|

吹瓶机规 Blower Specification |

动作压力 |

Action Pressure |

MPa |

0.8-1.0 |

0.8-1.0 |

0.8-1.0 |

0.8-1.0 |

0.8-1.0 |

0.8-1.0 |

|

吹气压力 |

Blowing pressure |

MPa |

2.5-2.8 |

2.5-2.8 |

2.5-2.8 |

2.5-2.8 |

2.5-2.8 |

2.5-2.8 |

|

|

机器尺寸 |

Blower size |

M |

1.45*0.65*1.6 |

1.95*0.85*1.6 |

1.75*0.65*1.6 |

1.95*0.85*1.6 |

1.95*0.65*1.6 |

2.2*0.75*1.75 |

|

|

机器重量 |

Blower weight |

T |

0.65 |

0.82 |

0.75 |

0.82 |

0.94 |

1.15 |

|

|

烘箱规格 Oven Specification |

灯管数量 |

Number of tubes |

PCS |

28 |

28 |

40 |

40 |

40 |

60 |

|

灯管功率 |

Power of tubes |

KW |

0.6 |

0.6 |

0.8 |

0.8 |

0.8 |

0.8 |

|

|

加热功率 |

Heating power |

KW |

16.8 |

16.8 |

32 |

32 |

32 |

48 |

|

|

烘箱尺寸 |

Oven size |

M |

1.8*0.65*1.4 |

1.8*0.65*1.4 |

2.25*0.65*1.4 |

2.25*0.65*1.4 |

2.4*0.65*1.4 |

2.7*0.7*1.6 |

|

|

烘箱重量 |

Oven weight |

T |

0.3 |

0.3 |

0.33 |

0.33 |

0.35 |

0.38 |

|

|

Actual output depends on bottle shape and preform qualification, the above technical parameters are subject to continual updates, please rake the real product as the base. |

|||||||||

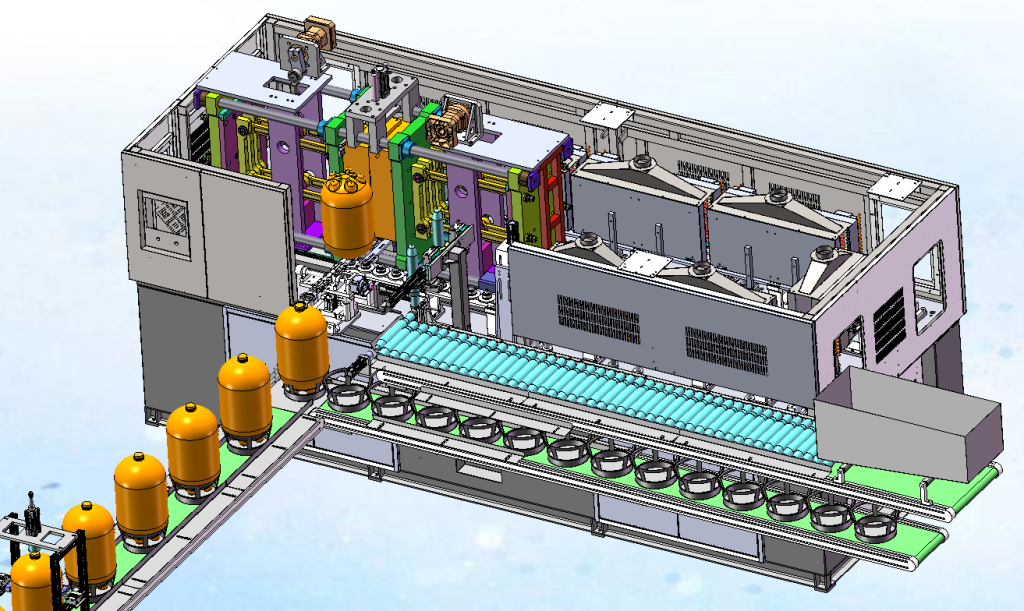

Full automatic blow machines

F Series Blow Molding System

Manufacturer: Taizhou Fupusi Machinery Co., Ltd.

Primary Function: Economical PET bottle production (100ml–30L) with space-optimized design

Core Attributes:

- Ease of Operation: Touchscreen interface with quick-start guides

- Maintenance Advantage: Stainless steel components minimize servicing needs

- Application Diversity: Compatible with water, oils, cosmetics, and agrochemical packaging

Technical Parameters:

- Volume Range: 100ml to 30L

- Supported Materials: PET, HDPE

- Production Speed: Up to 8000 bottles/hour

Core Competency:

Specialized in producing plastic packaging for:

- Beverage Sector: Mineral water, carbonated drinks, wine bottles

- FMCG: Edible oils, liquid detergents, cosmetic containers

- Industrial: Medical vials, pesticide containers

- Food Processing: Canned food packaging, hot-fill PET bottles

Technical Highlights:

✔ 100ml–30L capacity range

✔ FDA/EC compliant materials

✔ -40°C to 85°C temperature resistance

Plastic PET bottle Full auto blow machine

It is used for Bottle designs for water, carbonated drinks, oils, beauty products, and agrochemicals

| Item | Unit | FPS-600-4S | FPS-600-6S | FPS-600-8S |

| Cavity | PCS | 4 | 6 | 8 |

| Theoretical Output | BPH | 4800-5200 | 7200-7700 | 9600-10000 |

| Max. Volume | L | 0.65 | 0.65 | 0.65 |

| Max. Height | MM | 330 | 330 | 330 |

| Max. Diameter | MM | 66 | 66 | 66 |

| Neck Size | MM | 28-38 | 28-38 | 28-38 |

| Number of light tubes | PCS | 50 | 50 | 60 |

| Zone of Oven | PCS | 5 | 5 | 6 |

| Power of light tube | KW | 2 | 2 | 2 |

| Max. Heating Power | KW | 100 | 100 | 120 |

| Total Power | KW | 114 | 114 | 134 |

| Actual Consumption | KW | 22-28 | 22-28 | 28-34 |

| Operation Pressure | MPA | 0.7-0.85 | 0.7-0.85 | 0.7-0.85 |

| Action air consumption | M3/MIN | 1600 | 2000 | 2500 |

| Blowing Pressure | MPA | 2.5-3.0 | 2.5-3.0 | 2.5-3.0 |

| Blowing air consumption | M3/MIN | 2000 | 2500 | 3000 |

| Machine Size | M | 4.3*1.9*2.1 | 4.8*1.9*2.1 | 5.4*1.9*2.1 |

| Machine Weight | T | 5.5 | 6.5 | 8.5 |

Plastic Jar bottle full auot blow machine

It is ideal for the food, pharmaceutical, cosmetic, confectionery, honey, dried fruit, and large-scale plastic container industries

| ITEM | UNIT | FPS114.3-4 | FPS130-4 | FPS150-4 | FPS200-4 |

| Cavity | PCS | 4 | 4 | 4 | 4 |

| Capacity output | BPH | 3800-4500 | 3400-4000 | 3000-3200 | 2800-3200 |

| Max. Volume | L | 1.5 | 2.5 | 3.5 | 5 |

| Max. Height | MM | 330 | 340 | 350 | 360 |

| Max. Diameter | MM | 105 | 120 | 140 | 190 |

| Neck Size | MM | 90 | 107 | 127 | 177 |

| Number of Light | PCS | 40 | 50 | 60 | 84 |

| Zone of oven | PCS | 5 | 5 | 5 | 7 |

| Power of tubes | KW | 2 | 2 | 2 | 2 |

| Max. Heating power | KW | 80 | 100 | 120 | 168 |

| Total power | KW | 90 | 110 | 130 | 182 |

| Actual consuption | KW | 18-27 | 22-33 | 26-39 | 36-55 |

| Operation pressure | MPa | 0.75-0.85 | 0.75-0.85 | 0.75-0.85 | 0.75-0.85 |

| Action air consuption | M³/min | 1600 | 2000 | 2500 | 3500 |

| Blowing pressure | MPa | 2.5-3.0 | 2.5-3.0 | 2.5-3.0 | 2.5-3.0 |

| Blowing consumption | M³/min | 2500 | 3000 | 3500 | 5000 |

| Machine Size | M | 4.3*1.9*2.1 | 4.6*1.9*2.1 | 4.9*1.9*2.1 | 6.5*1.9*5.8 |

| Machine weight | T | 4.5 | 5.0 | 5.5 | 7.5 |

20L & 5 gallon & Big container machine

Oil industry: 5L-20L PET bottles

Beverage sector: 10L -30L beer barrels

Bulk Containers: Reusable gallon jugs

|

项目 |

Item |

unit |

FPS5L-1 |

FPS5L-2 |

FPS10L-1 |

FPS20L-1 |

|

|

瓶型规格 Bottle type Specification |

腔数 |

Cavity |

PCS |

1 |

2 |

1 |

1 |

|

理论产量 |

Theoretical Output |

PCS/H |

600-700 |

1200-1500 |

500-600 |

450-550 |

|

|

最大瓶子容量 |

Max. Volume |

L |

5 |

5 |

10 |

20 |

|

|

最大瓶子高度 |

Max. Height |

MM |

400 |

400 |

450 |

490 |

|

|

最大瓶子直径 |

Max. Diameter |

MM |

180 |

180 |

220 |

250 |

|

|

瓶子口径 |

Neck Size |

MM |

38-48 |

38-48 |

38-55 |

38-65 |

|

|

电力规格 Power Specification |

灯管数量 |

Number of tubes |

PCS |

36 |

60 |

36 |

36 |

|

烘箱区域 |

Zone of oven |

PCS |

3 |

5 |

3 |

3 |

|

|

灯管功率 |

Power of tubes |

KW |

2 |

2 |

2 |

2 |

|

|

最大加热功率 |

Max. Heating power |

KW |

72 |

120 |

72 |

72 |

|

|

总功率 |

Total Power |

KW |

80 |

130 |

80 |

80 |

|

|

实际耗电量 |

Actual consumption |

KW |

15 |

25 |

15 |

15 |

|

|

空压规格 Air Pressure Specification |

动作压力 |

Operation pressure |

MPa |

0.7-0.85 |

0.7-0.85 |

0.7-0.85 |

0.7-0.85 |

|

动作耗气量 |

Action air consumption |

m³/min |

1000 |

1600 |

1000 |

1000 |

|

|

吹气压力 |

Blowing pressure |

MPa |

2.5-3.0 |

2.5-3.0 |

2.5-3.0 |

2.5-3.0 |

|

|

吹气耗气量 |

Blowing air consumption |

m³/min |

2000 |

4000 |

3000 |

4000 |

|

|

机器规格 Machine Specification |

机器尺寸 |

Machine size |

M |

2.1*1.5*1.85 |

4.0*1.75*1.85 |

2.3*1.5*1.85 |

2.5*1.5*1.85 |

|

机器重量 |

Machine weight |

T |

2.9 |

4.5 |

3.5 |

4.1 |

|

|

Actual output depends on bottle shape and preform qualification, the above technical parameters are subject to continual updates, please rake the real product as the base. |

|||||||